Services

SPECIALISATION AND FLEXIBILITY:

WE FOLLOW YOU IN ALL PHASES OF THE WORK

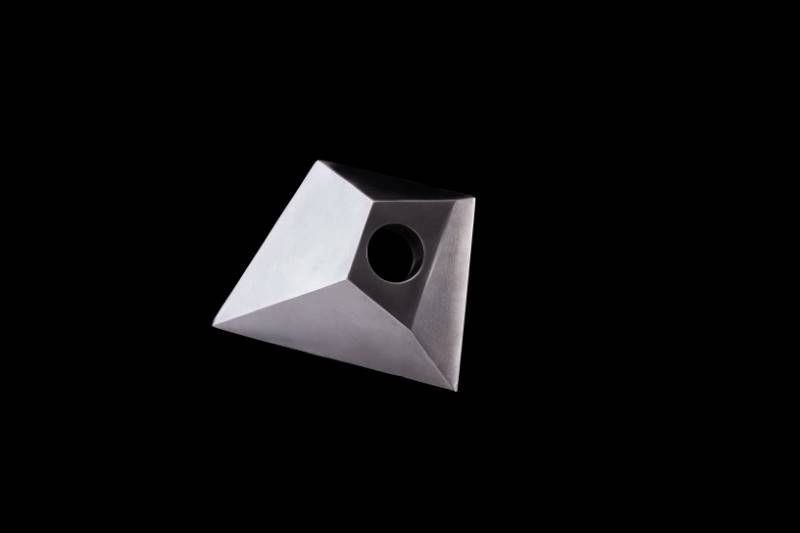

CONTROLMEC operates in the most varied sectors of mechanics including architectural engineering, bioenergy, the food sector, the automotive sector, the mold industry etc.

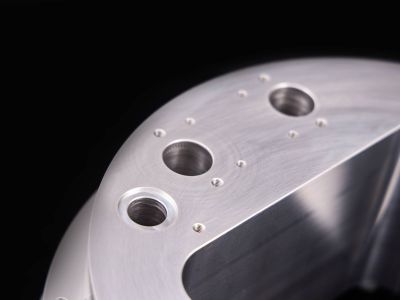

Multi-materials

Thanks to highly specialised personnel, the machine is equipped with common or ad hoc systems. Equipment and experience enable us to carry out processing also on plastics, aluminium, various types of metals, special alloys, and very hard materials (hardened, case-hardened, carbonitrided, etc.)

Turning and Threading

Precision, speed, quantity... each process requires a good level of experience and the right machinery to guarantee the end result at the right price.

Milling

Machining is done by CAM programming for more complex parts or directly on the machine for simpler ones. The staff, which already has a wealth of experience, is constantly trained in techniques and machining.

Various processing

After assessing the feasibility, we proceed with the drafting of a quote in the shortest possible time, calculating the cost and time for the final realisation. We work both under contractual work and on consignment by directly procuring the material.

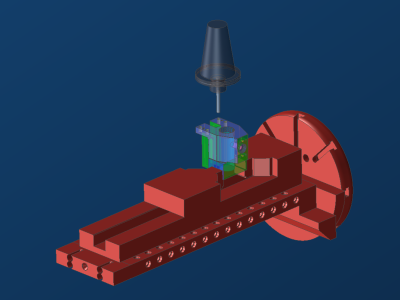

CAD/CAM

The production of the required parts starts with the receipt of the sample and/or drawing in the different 2D (dwg dxf and pdf) or 3D formats (.iges, .xmt, .par, .3dm, .stl, .sldprt and .x_b), the latter being necessary for the most complex machining operations: thanks to the Gibbscam CAM software, digital models can be implemented and manufactured.

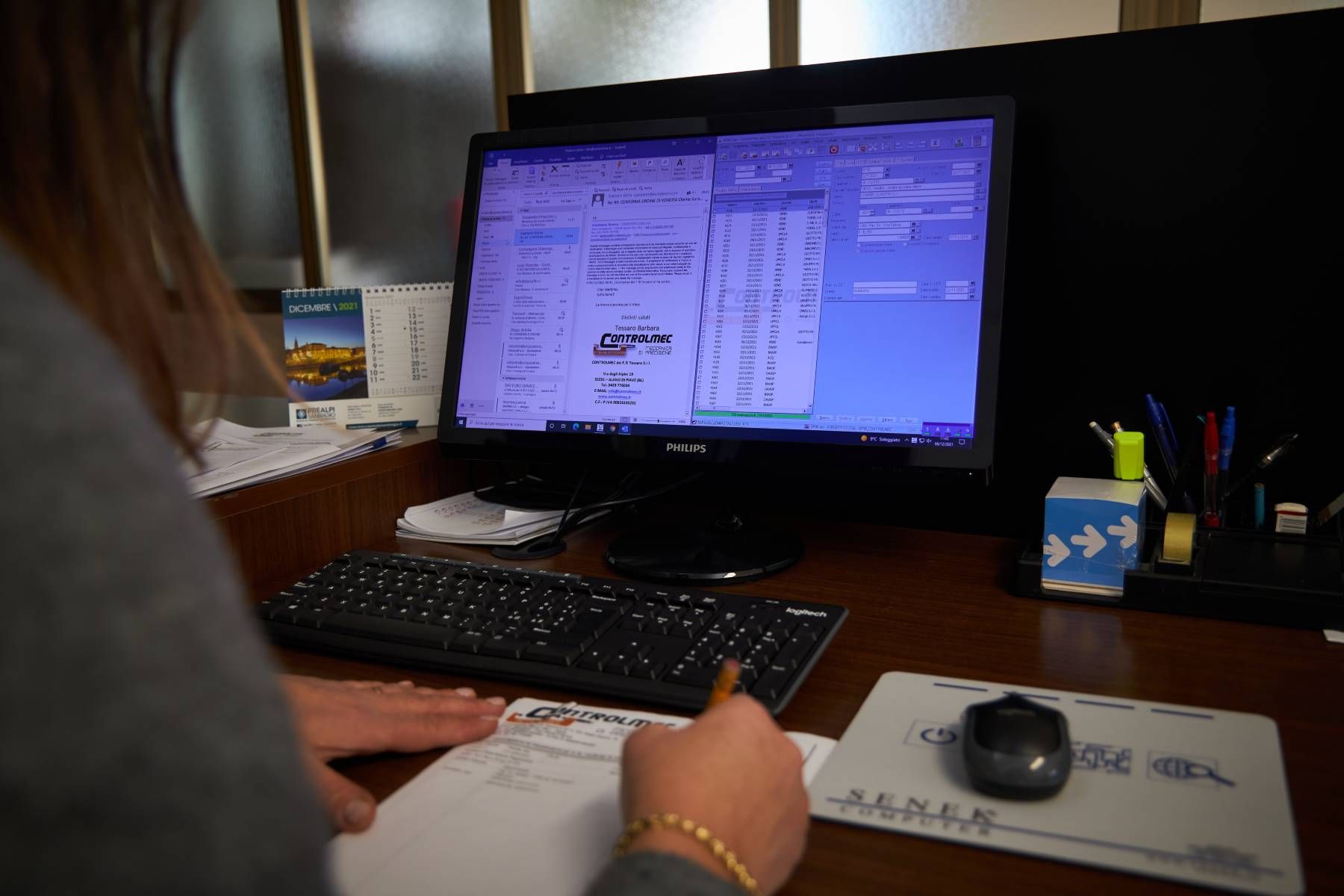

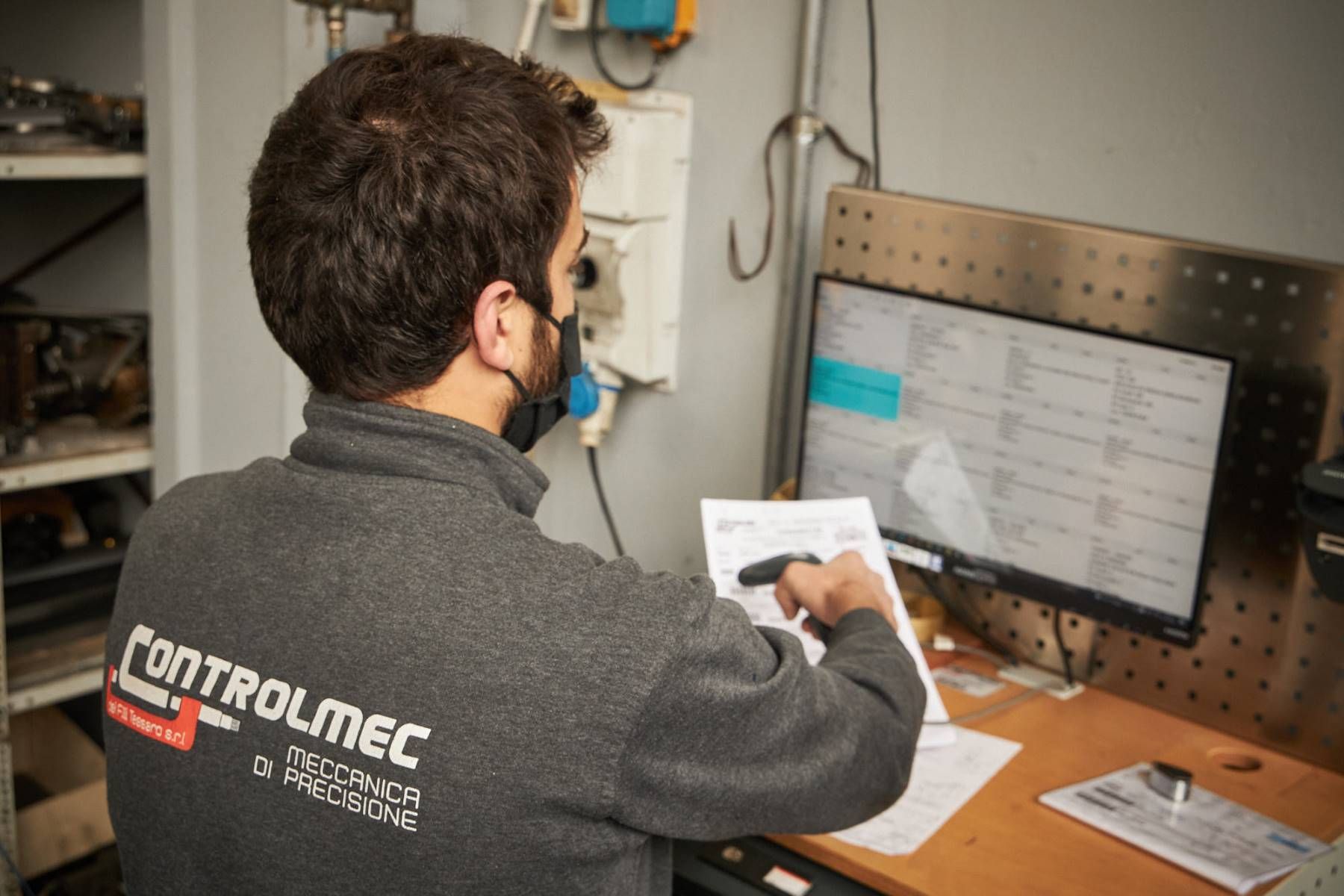

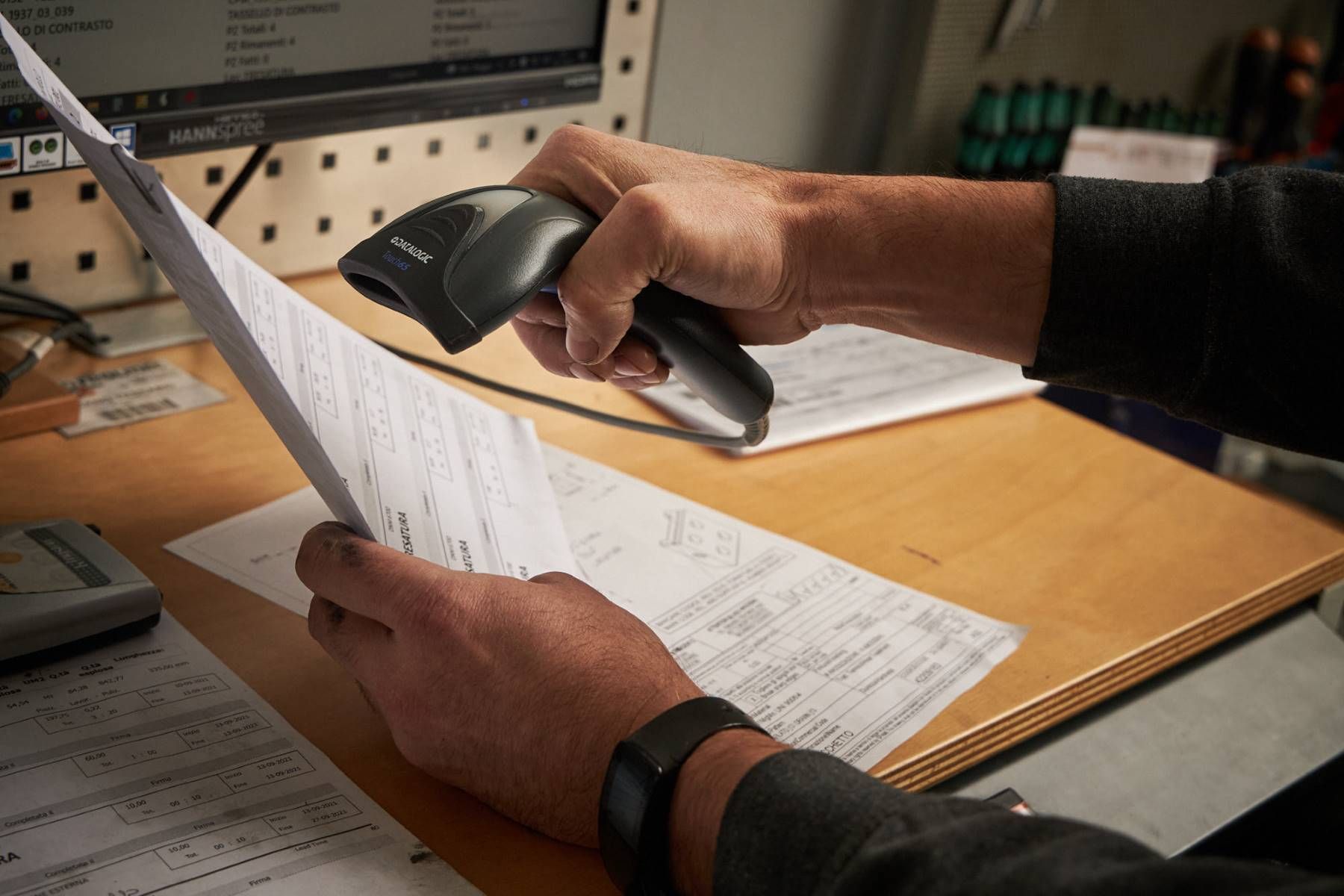

Management automation

Flexibility and specialisation: over the years the work of the Tessaro brothers has developed and adapted according to customer needs. Controlmec supports its customers in all the steps of the production cycle, from quotation to delivery.

With the help of the management system, all steps are planned, also minimising unforeseen events due to employees and suppliers.

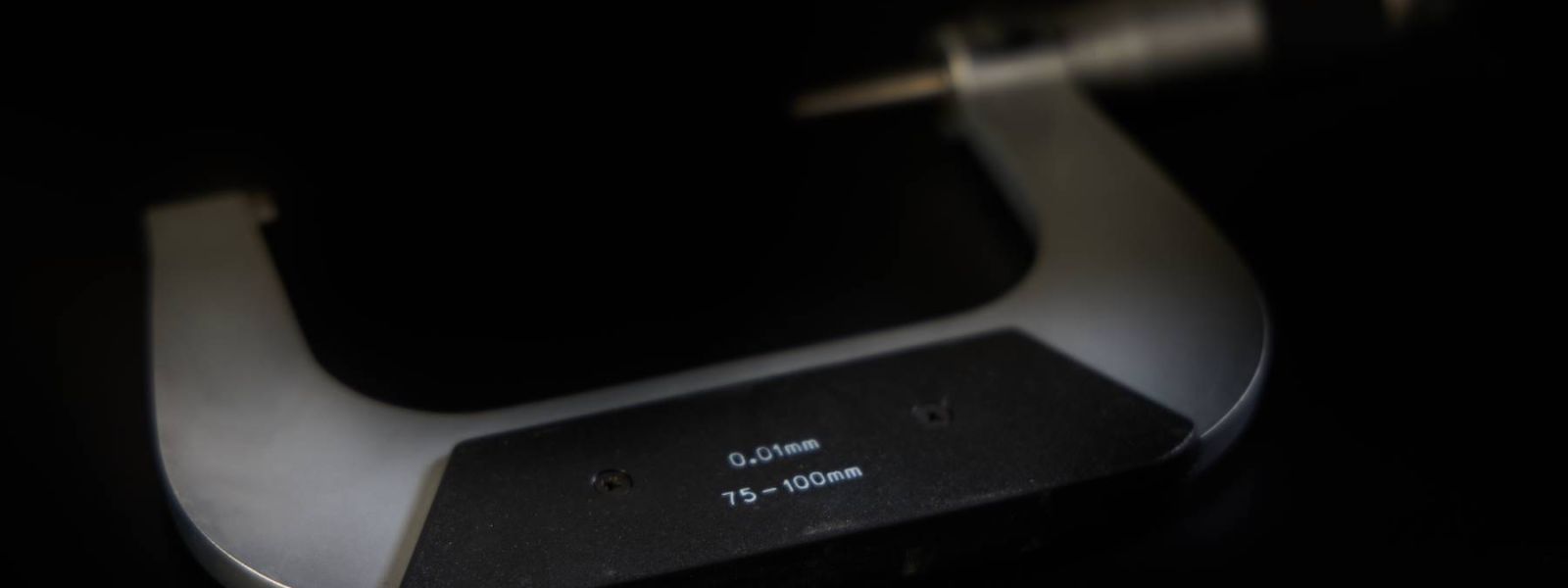

Finishing

Thanks to our cooperation with specialised companies, we can meet a variety of treatment and finishing requirements. Both during production and prior to final dispatch, random or full quality checks are carried out according to specific requirements. The checks are carried out using appropriately calibrated instruments in a dedicated area.

Logistics

In order to support the customer throughout the entire production cycle, CONTROLMEC has optimised the logistics management of warehouse and delivery, also supplying the products in customised packaging at the customer's request. We have 2 internal 5 tons overhead cranes and one external 6 tons double trolley overhead crane for handling the heaviest workpieces, as well as 2.5- and 6-tons forklifts.

Possibility of delivery ex warehouse, express courier or by our own means

Front office

From the first contact to service, the facility is supported by an administrative department that analyses and identifies solutions. From the order proposal handled in person, work is entered and monitored by the management system, to manage time and work schedules optimally and flexibly.